After Sales Service

We show our presence in India We adhere to the principle of Customer priority, encourage employees to care about customer demand, and provide solutions for customer.

We have over 30 after-sale service staff, with our service penetrating to prefecture-level city, and provide 24h door-to-door prompt and thoughtful service for customers.

Service commitment: One year free repair and maintenance for complete machine, 24h door-to-door fast response, 7x24h consultation service, Establish user file for follow-up service When there is a problem, you just need to call the service hotline 98963 27066 or 0184 4066066, or leave a message to E-mail:info@uniquesorter.com, No matter where you are, you can visit our website

Installation Conditions for The Machine

1. Site requirements

The installation site should be flat and solid, and the constructed working platform should be away from strong vibration sources like the polishing machine and white rice grader.

The elevator should be installed before installing the color sorter so as to prevent damage to the color sorter caused by the falling welding or hard objects.

The installation site for compressor and air tank should be away from the crowd so as to reduce noise pollution or other possible injury. Also, users are recommended to keep the compressor and air tank in ventilated and dry place, thus keeping the compressed air clean and dry.

2. Environmental requirement

Like the common domestic appliances, in term of ambient temperature, the color sorter is required to be below 35 Degree so it is recommended to construct AC room in areas with high temperature and greenhouse in areas with low temperature.

3. Light requirement

As the external light will directly affect the color separation, it is necessary to keep the color sorter away from strong light and forbidden to put a ceiling lamp above it. Enough lighting, of course, is necessary for the operation and maintenance.

4. Maintenance space

Enough space around the color sorter is necessary for debugging and maintenance, and the recommended space around the sorter is above 60cm.

5. Ground wire requirement

As grounding the sorter can avoid the lightning strokedamage to the machine or any personal damage due to current leakage which resulted by misoperation, users are recommended to embed ground wire before welding the platform.

To prevent interference, individual wire with ground resistance no more than 4or the color sorter.

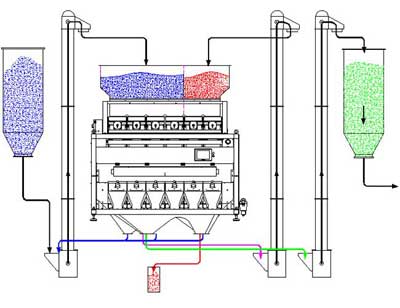

Installing color sorter

Before installation, the user should, in accordance with the equipment platform size drawings, construct the color sorter working platform, with platform elevation about 1.5m, and platform firmly and levelly welded.

As the color sorter is the Unique equipment, any mechanical deformation resulted by vibration must be avoided in carrying.

Customers are strong recommended to transport with forklift or crane. If crowbar is used as conditions not permitting, the cushion wood used in carrying should not be removed until the color sorter is moved nearby theplatform, then place the sorter on the platform by the hoist type crane or other ways. After which, adjust the levelness of the equipment within 2mm/1000mm by the leveling instrument.

Align the aggregate bin of the color sorter to users' feeding pipe which should be equipped with flow control plate and storage bin and not press on the aggregate bin, or color sorter's working efficiency will be affected.

Note:personal injury or mechanical faults would be caused by improper installation position.